OUR MISSION

Cheshire Stereo have been operating for over nineteen years, working hard to firmly establish ourselves as a high quality, reliable and extremely competitive printing plate manufacturer.

As a company we have developed and grown bigger and better from year to year and have recently invested heavily in new plant equipment.

With a firm belief in customer care, we at Cheshire will go above & beyond to ease your production headaches with regards to your printing needs.

Our customers can be assured of a high quality service backed by our expertise and wealth of experience within the printing industry.

WHAT WE DO

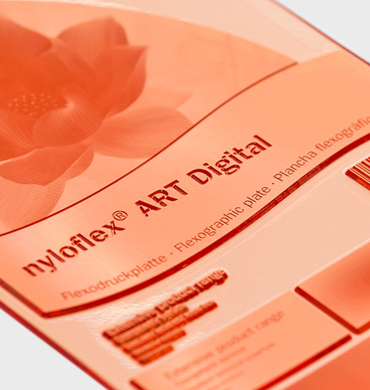

Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate, including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process uses quick-drying, semi liquid inks. In this age of digital printing, flexography holds its own in the areas of large orders and long print runs, particularly of packaging products.

Flexographic printing uses flexible photopolymer printing plates wrapped around rotating cylinders on a web press. The inked plates have a slightly raised image and rotate at high speeds to transfer the image to the substrate. Flexography inks can print on many types of absorbent and non-absorbent materials. Flexography is also well-suited to print continuous patterns, such as for gift wrap and wallpaper.

Unlike the individual sheets of paper used in offset printing, the rolls of material used in flexography allow large orders to run with few interruptions to reload the substrate.

Advantages

The flexographic printing process:

– Runs at extremely high press speeds

– Prints on a wide variety of substrate materials

– Uses cost equipment that requires little maintenance

– Uses relatively low-cost consumables

– Is ideally suited for long runs

– Handles all printing, varnishing, laminating in a single pass

Designing for Flexography

Like all types of printing, flexography has specifics relating to types of proofs, template and die cut specifications, issues with knockouts, drop shadows, fonts, tints, ink colours, image resolution and image formats. The design and file preparation affect the quality of printing you get from flexography, so mastering its specific requirements — some of which differ from the more familiar offset printing — is essential.

With our wealth of experience Cheshire's in house design department are on hand to create artwork that we know will work when it comes to printing the job, without any unwanted surprises such as filling in, overprint, registration etc.

Peter Hancock

Managing Director

Sharon Hancock

Accounts

Neil Parker

Production Manager

Barry Harris

Pre Mounter/Platemaker

James Malone

Account Manager

Jack Roberts

Apple Mac Operator